The Grazier's Math: Calculating Paddock Size, Stocking Rates, and Rest Periods

Animal Units, Paddock Sizing, Fencing, and more!

I know, you figured after 40 pages of reading about grazing, what more could you ask for other than even M O R E grazing content? I’m running out of puns at this point, so bare with me while I try to figure out how to talk like a normal person here.

Previously, we covered the role of grasses and nitrogen fixers in building resilient pasture field, the role of both C3 — cool season— and C4 —warm season— grasses, and how a basic understanding of how these grasses grow can help us optimize our pastures to maximize production. We further talked about grass management and how to successfully graze without overgrazing. We also talked about the functional role of paddocks within a pasture, and the mix of art and science that goes into sizing paddocks, and how we can use the fundamental knowledge we have in soil formation to be better at reading our landscape and predicting how quickly our paddock rotation needs to move. Further, we talked about how this is an evolving practice as your soil and pasture quality improves, and how seasonality can impact this process. With all that out of the way, we’re going to take some time to talk about some of the other aspects of pasture systems, starting with fencing options.

Generally, folks will think of the traditional split rail fence when you talk about farms, but generally these aren’t really used in any meaningful way, especially not in the systems we’re talking about. The most common fence on any given farm or homestead is likely a flexible steel fencing, called woven wire fencing, attached to metal posts that easily pop in and out of the ground called T posts. The flexible steel fencing is usually sized for specific animals, for example, you may see horse fencing, which has bigger holes and is tall, hog fencing, which has smaller holes at the bottom and generally is not as tall of fencing, and so on. This type of fencing is fairly cheap if you buy in large sizes, say $0.70 a foot or so, compared to $10 for wooden picket fence, and is a great semi-permanent option since, while it is a bit of a pain to move it, it’s not impossible, and if it’s something you’re only moving a couple times a year, it’s not bad at all. Posts are usually spaced 10-20 feet apart, depending on what you’re fencing in and if there’s going to be pressure on it, as well as the terrain you’re fencing in. You can use a sledgehammer to hit the T-posts in, but if you’re going to be putting in more than a few of these, get a post driver and you’ll be saving yourself some time, effort, and probably some skin on your hands.

I personally like to use woven wire fencing more than the other options for a few reasons, which I’ll cover later, but ultimately I favor low-tech over high-tech when there isn’t a significant difference in terms of time savings. The reason I’m bringing this up now is because we’re going to jump into the hot new (relatively speaking, and pun intended) tech in agriculture, electric fencing, called high-tensile fencing.

Electric Fencing

High-tensile is a type of smooth wire fence that is electrified to keep animals contained. It is probably the most widely used type of perimeter fencing. High tensile is very economical and works well for keeping livestock - especially cattle - contained. Electric fencing is designed to be extremely mobile, and just like woven fencing, is designed with different heights, thicknesses, and spacings based on the animal the fence is supposed to be used for. For smaller animals like chickens and ducks, and for animals that are escape artists, like, ahem, goats, a type of mesh netting can be used, and is common on smaller farms. However, this type of fencing becomes bulky very quickly when moving it, and because of that, comes with a whole host of other requirements, and most folks running more than a hundred feet of this fencing will often use a quad or tractor with specific equipment to pick up and move the fencing, which, with the additional costs of electrified mesh fencing, adds up extremely quickly. The mesh fencing with the charging system and the grounding rod will typically run you around $3 a foot, so a bit more than woven wire, but still significantly cheaper and more effective than split rail fencing.

Outside of the mesh netting, typically, two or three of the wires are electrified using a fence charger, looking more like traditional fencing than the netting. Subdivision or internal fencing might only consist of 1 to 3 wires between paddocks. Generally, the animals know not to try and escape the fencing once they’ve been shocked once, and the additional wires on the outside are to keep wildlife away from your animals. If they don’t seem to be learning, you’ve got one of 4 issues: 1) Your grounding rod isn’t deep enough, 2) You’ve got a short somewhere, 3) You need more wires (animals with very heavy coats to protect them will try to wiggle underneath for a bite, for example), or 4) It’s not powerful enough. I’ll save you time now; most solar powered fencing is not going to be strong enough for something to learn electric fencing on.

Posts in high-tensile systems are generally placed 20 to 40 feet apart, depending upon terrain, with 4 to 6 wires stapled to the posts for perimeter fencing. Droppers are vertical posts that wires run through the wires to add rigidity to the fence when posts are long distances apart or when fencing travels over very uneven ground. They are on the fence but not placed in the ground, with the advantage of being less expensive and less labor than installing an additional fence post. So, for example, you may have the option of placing a post every 20 feet without droppers, or you could space out the posts to every 25’ feet with droppers in between posts. One of the challenges with this system, particularly when it comes to the smaller 2 wire system, is that if something spooks your animals, they will blow through the electric system, even if it hurts them, and there’s no physical barrier to keep them back like with a traditional fencing system.

The major benefits of high-tensile systems is the low cost and the ease of moving fencing. At less than fifty cents a foot all-in, it’s about half the cost of woven wire, with the added benefit that it will keep your animals safe from coyotes or whatever wildlife issues you worry about— assuming you’re using at least 2, probably 3 wires, in my experience. There’s a reason why high-tensile systems are the fastest growing systems in use today; it’s affordable and more effective than just about every other system, with some drawbacks, as we stated before.

Post and rail, split rail, or board fence can also be used, but, like woven wire, it is much more expensive than high-tensile fencing. If you’ve got cedar, locust, or osage orange trees nearby, these are fantastic options for making your own system from wood on your land, and if you’re coppicing the locust or osage orange, you can grow your own posts in bulk in as short as 5 years, making them extremely sustainable. A single strand of electrified wire is often installed on the inside of these fence systems to prevent animals from pushing through the fence or damaging fencing when trying to graze on the outside of the pasture. Alternatively, you can use a woven wire with a post and beam system to keep smaller animals from escaping and adding rigidity to your woven wire fencing. I've had particular success with woven wire fencing paired with electric fencing, as it is more effective with multi-species grazing and it is particularly helpful with sheep who are new to electric fencing.

Obviously, though, electric fencing is a challenge compared to other systems because it’s not something you just install and you’re done. When you’re dealing with electricity, there’s risks that come with it, and inputs required. First, as I inferred previously, electric fences need to be “grounded” to properly carry the electric current through the fence wires. To ground an electric fence, you’ll need to drive 6-foot-long galvanized “ground rods” into the ground. The amount of rods depends on the size of the fence; for most people doing backyard-type pastures, 1 rod will probably be enough, but 3 is a good safe bet. Select an area that remains moist throughout the year, if possible. Separate ground rods by at least 1½ times their length, then drive each rod at least 6 feet into the ground. Attach the first ground rod to a non-electrified wire, then hook the rods up in sequence.

Further, weeds and grass must also be controlled under electrified fences. If you’re working a large property, this can become a major project with a weed wacker or scythe. Additionally, this requires some additional planning because if you’re moving fence daily or every few days, you’ll need to prepare the space where the fence is going in advance so that you’re not rushing to clear space so that grass doesn’t short out your electric fence. Now, I could probably do an entire episode just on the different parts of high-tensile systems, because there are various parts involved, various qualities, solar system sizes, system portability, and voltage concerns, but I think this at least covers the basics and the major pros and cons of each system.

Part of why I use some limited mesh fencing on my property is because I wanted to try it out, and I do like it, but it can become extremely cumbersome quickly, and I do have concerns about its long-term usage, as it tends to tear easily, which is concerning given the higher price-point. Further, even though it is used primarily for poultry, it still has no effect on birds, and is a bigger deterrent for predators, assuming your flock doesn’t figure out how to force themselves through the wire. High tensile systems are better in this regard, since the wires are thick, and storing things like insulators and wire couplers are much more practical. That said, they’re a bit more of a challenge for chickens, ducks, piglets, and depending on the landscape, even larger animals.

Water Access

With that covered, let’s jump back into the conversation on water. Once you’ve got your paddocks sized and spaced out, especially when systems are still being sized correctly, creating water sources can be a bit of a challenge. Remember that the goal is to provide water within 800 feet of anywhere in a paddock.1 For many people, that’s simple; their few acres doesn’t have any paddocks larger than 800 feet. Great. That said, it’s still worth thinking about how we’re making water accessible. The further animals have to travel for water, the more feed energy they’ll expend on walking, instead of putting that energy into production, and the less likely the animals will graze equally across the paddock. For most of us on small properties, this isn’t going to be much a problem, and I’d be surprised if anyone listening to this is going to have this size problem, but I do want to make sure it’s been said.

Temperatures play a large role in the amount of water that animals consume day to day as well. As temperatures increase from 50 to 90 degrees Fahrenheit, water requirements can more than double.2 Females that are nursing young will also have additional water requirements to be able to produce adequate quantities of milk. Finally, forage moisture influences the amount of water required by animals each day. Sheep and goats can often meet their daily water needs when grazing lush forage in the spring.

There’s a lot more we could cover around water consumption and infrastructure, and it’s something we’ll cover in further detail at another time. That said, some areas we can look at for creating water sources is to have semi-permanent water systems in place, using things like pond liners, shallow buckets, although size will be largely dependent on how many animals you’re grazing. If you’re looking to save money, it makes sense to make the watering container moveable, but obviously that comes with more labor involved. Additionally, with moving watering systems, it’s important to have access to water, which may mean long hoses, or PVC piped water lines around your property, which can be tied into the water lines of your house or can be tied into a rain barrel water collection system, if you have the opportunity to pitch water or if you have a water pump attached to your rain collection system. You can also consider some more labor intensive options that are more natural, like farm ponds and smaller gley ponds, which act much like vernal pools (and are a widely underutilized and under-researched technique, in my opinion).3 I've had some success with duck gleyed ponds, something I'll definitely be diving further into at another time. Much like with the electric fencing systems, the larger your property, the more it makes sense to consider some ability to travel across your property on something like a quad or tractor that can move equipment quickly. Since I’m interested in stay generally low-tech, because of the goal of this podcast, it’s a reminder of our need to be very thoughtful in our planning in order to minimize the need to create this type of workload.

The main thing that you should take away from all of this is that there is no simple plug and play system. There are examples of successful variations of all types of grazing systems. As a grazing manager, this allows you a certain amount of independence. However, with that independence comes the responsibility to learn and experiment to see what will work on your farm. Before we move on to discuss types of grazing systems, we need to define what we mean by "dry matter". Dry matter is an important concept to understand when it comes to grazing management because it is the term we use to describe yield in a pasture. We’ve spent a lot of time talking about biomass, and the role of pasture species in making useful biomass, but we haven’t talked much about any measuring techniques other than the minimum heights we want to aim for when grazing. Consumption can be estimated by using the weight of the animals multiplied by a percentage figure. Cattle and small ruminants— that is, goats and sheep— will consume approximately 2.5 percent to 3.0 percent of their bodyweight in forage dry matter per day.

Managed grazing helps us to control when and where our livestock are grazing, allowing us to ensure that we are feeding them the highest quality forage at the optimal time of production. Whether you have been studying or practicing grazing management, you’ve probably heard many terms to refer to various grazing management systems and philosophies: Some examples include continuous grazing, rotational, intensive rotational, management intensive, strip grazing, mob grazing, high density, ultra-high stock density, and holistic grazing

And the list could go on. To further complicate things, with the possible exception of continuous grazing, most of these terms are not well defined and overlap. There is no cookie cutter way to successful grazing management.

If you’re new to grazing livestock, start by getting the basics done right. Make some divisions in your pastures to allow paddock rotation and rest periods for the forages. Use temporary fencing for interior subdivision. This will allow you to adjust how you set things up later in the season or perhaps next year.

Work with the system, keep records, and gain experience. As you become comfortable with managing the system, you can intensify your management when the time is right. If you’re new to grazing livestock, start by getting the basics done right.

Rotational Grazing

There’s 4 important areas to consider when you want to graze animals— managing the nutrients of the plants grazed as well as the animals grazing, controlling parasites among your livestock, prolonging your season as long as possible, and maintaining optimal grass height. Managed livestock simply means you control where and when they feed. Paddocks are the primary tool for this. Managing these paddocks allows recovery time for various areas of pasture. Generally, grasses and other forage are full of higher sugar, more digestible proteins at younger ages, but those dry matter we had talked about earlier is low— ideally we want to get the livestock to forage when the dry matter starts to accumulate but before the edibility of the plants as begun to ween. You might think that if we let the grasses grow larger will provide more dry-matter and ultimately a higher yield, but you actually will get a higher yield over the long-term from foraging younger greens.4 If we think back to one of the earlier episodes on soil, we had talked about how many greens co-evolved with foraging species, and actually stimulate growth from the process of being grazed upon.

Continuing with what we had talked about in the soil episodes, we had talked about the idyllic farm pasture, with a cow chewing on some grass, moving here and there, but with the field at his disposal in what’s called a continuous grazing system. Continuous grazing is the simplest grazing system. In the continuous grazing system, the pasture is not divided into sub-pastures (paddocks). Livestock have access to all the pasture area at any given time throughout the entire grazing season.

This system involves a very low level of labor and management. It also requires very little expense in fencing materials other than the exterior fence. Furthermore, the water system can be minimal— not ideal, but it can be.

However, there are many disadvantages to not rotating pastures. These include uneven grazing patterns (spot or selective grazing), a variable plane of nutrition (animals eat the best forage first, then move on to lower quality forage, and continue to overgraze their preferred forage, never allowing it to seed and often die), uneven distribution of manure and resulting ‘nutrient creep’ toward water and shade, change in pasture botanical composition over time favoring plants that are not readily grazed, and overly mature forage or severely overgrazed forage, all in the same pasture.

Rotational grazing can mean different things to different people, but it generally refers to dividing the pasture into those sub-pastures called paddocks. The basic premise with rotational grazing is that it will allow the pasture plants a rest period to regrow before being grazed again.

There might be only a few paddocks through which livestock are moved every few weeks, or there could be many paddocks with livestock being moved every few days. The basic premise with rotational grazing is that it will allow the pasture plants a rest period to regrow before being grazed again. Compared with continuous grazing, advantages of rotational grazing include that livestock are on a more even plane of nutrition, rotationally grazed pastures typically yield more, and you get a more stable botanical composition in your pastures.5

The obvious disadvantages for rotational grazing include that it requires more labor to set up paddocks compared to continuous grazing, and it is more expensive than continuous grazing due to the materials and infrastructure that are necessary (temporary fencing, access to water in all paddocks).

It’s important to understand with rotational grazing, we don’t typically work around a calendar year but rather the plant characteristics of the paddocks. If you recall, we have various greens, some which accelerate their growth in different times of year, and those will impact which paddocks should be foraged.

This sounds complicated, and, to an extent— it is. We’re just going to cover some really basic components of it, since I know it’s not what everyone’s primary interest is. Your first question might be— at what point is it time to move animals out of a paddock so it can rest? With perennials and cool-weather annuals, generally they should not be grazed below 3 inches. Leaving 3 inches of residue keeps the plants healthier so they can regrow quickly while maximizing animal growth.6 This further allows the plants to continue to grow their root mass, making them more resilient. Further, parasite larvae tend to stay at the bottom 2 inches of the grass limiting exposure to those parasites.7 Additionally, your plants generally start regrowth at around 5 days, so moving the animals at that point will reduce extensive grazing on preferable species. Referring back to the parasite issue, generally parasites will take 6 days to develop from larvae, further reducing the risk of parasitic infection.

This brings us to the question of rest. We want the paddock grasses to reach an absolute minimum of 6-10 inches tall before allowing the animals back in for grazing. 8 At this height, they have enough weight with enough sweetness to be attractive and provide a meaningful amount of calories for our animals.

That said, that changes by species. If the species of grass you're growing, like, say, Kentucky Bluegrass, tends to be on the smaller side, that may change your expectations of what is an acceptable height for grazing. For most parts of the country, during the spring, when the temperatures are cooler and you’re getting lots of rain, you’ll want to do what’s called flash grazing, where the animals only come in for a short period of time to trim the extremely fast growing grasses down, and during the hot dry summers your rest period may be up to 60 days. One study suggested that the ideal time to rest a paddock for maximum biomass and palatability was between 14 and 28 days, but of course, that's contingent on a number of factors including rain, temperature, soil type, and pasture composition.9

Strip grazing is a type of rotational grazing. It is the best method of managed grazing for stockpiled pastures, annual forages, and crop residue.

In these types of forages, it is critical to sub-divide the larger area to optimize the use of available forages and reduce waste. We can use single strands of temporary fence to sub-divide larger areas of forage into strips. This type of grazing is common on larger fields of monocrops and is a good way to use up the green residue from a field, and is a great way to break down stalks from larger plants, say, corn, so that the nutrients are quickly accessible in the soil. Typically, we allocate strips for very short durations of a few hours up to three days. This creates a more competitive atmosphere, which encourages the livestock graze more of the available forage.

Ultra-high stock density (UHSD) grazing is also known as "mob grazing". Although not completely defined, these terms generally refer to situations where animals are stocked very densely - from 500,000 to 1 million pounds of animal per acre in some cases. The herd is moved to new pasture very frequently to allow very long rest periods for the pasture (60 to 90 days, or perhaps longer). Some of the forage that is not consumed is trampled into the soil to build soil organic matter. UHSD grazing has not been well-researched, but promising research has come out without peer review. In terms of peer reviewed content, there seems to be a dampening of that optimism, with suggestions that because of the long periods between grazings, the quality of forage is down, and because of the density of grazing, "trampling of the forage... could speed up oxidation of organic matter and therefore decreas[e] carbon sequestration."10 Much like many new areas of research, it seems that it’s better than the nay sayers suggest and not as good as the proponents promise. One major disadvantage is that it is very time intensive. It takes a lot of time to move animals every day, especially for smaller herds, which may not be practical for people with off-farm jobs.

The Animals

Species and class of grazing animal may determine the grazing period. Since lactating dairy cows need consistent forage quality, the grazing period for them may be anywhere from half a day to two days. However, for beef cows and brood ewes, forage quality consistency is important, but not as critical as with lactating dairy cows, so longer grazing periods, say, 3 days, where they eat the good stuff first and less desirable forage later will suffice.

Using your land resources to develop a pasture system that fits in with your total animal, forage, and crop program is an important first step in pasture management. Our goal is to provide quality pasture for the grazing animals throughout the grazing season.

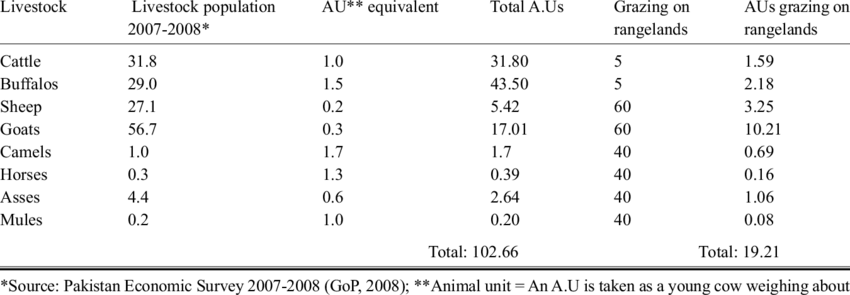

The first step to rotational grazing is to determine the forage requirements of your herd or flock. We determine this based on something called animal units (AU). One animal unit is based on the amount of daily dry matter forage intake of a 1,000-lb dry cow (about 25 lbs/day). 1 AU = 1,000 dry cow. Dry matter forage intake varies by animal species and class what stage of growth they are in. However, there is a lot of variation to this methodology and you can make it as complicated as you want, measuring by species of grasses and forbs, density of those grasses and forbs, and breaking AUs down into AUDs, that is, Animal units per day, and AUMs, animal units per month. We’re going to stick with basic, annual AUs.

Since a lactating cow has higher nutritional requirements than a dry cow of the same weight, her AU is higher. For context, a bull is typically around 1.0 AU, a sheep is around .15 AU, an Angora goat is around .12AU, a full-grown pig is around .4AU, Ducks are around .01, and a chicken is .014. And as you can see, the numbers I refer to are slightly different than the graph above, because there’s a lot of variation in each of these species. If you have, like me, 20 egg-laying chickens and ducks at .014 AU and 2 sheep at .15Au, your total AU is 0.58, or just around half an Animal Unit.

Now that you know your total herd animal units, you need to estimate how many acres you'll need throughout the grazing season. Estimating the number of acres required to pasture a herd or flock depends on the feed requirements of the animals and the available forage produced. Since pasture growth is variable — dependent upon things like plant species, soil characteristics, topography, fertilization, temperature — we can only estimate the number of acres required for grazing animals. Actual acreage will also depend on pasture yield, dry matter intake, and efficiency of pasture utilization.

I’m going to use orchard-grass and white clover— with a summer-seeded brassica—the family of cabbage, broccoli, and cauliflower, to extend the season— as a basic example of what kind of production you can have. Averaging out the year, you can grow about 1 AU of forage on just about 3/4 of an acre from May through late November for your animals. For me and my example of 20 chickens and ducks and 2 sheep, they can survive on half of that from May through late November, and that’s not including leftover fruits, veg, scraps, and green waste from my garden.

Of course, it’s not that simple. Like we said, certain species have a fast growing season, and then slow down. Trying to blend those different seasons by using a diversity of cover crops can help maximize each seasonal grower to help feed your livestock. As much as it is a science, we are required to make a series of assumptions, and further, we are better off attempting to overproduce on our field than underproduce, as we tend to underestimate our animals’ needs and overestimate the health of our pasture.

We already know the AU of my example herd, .58. Now, let's learn how to calculate the available pasture, based on your desired grazing period. Then, we'll talk about the grazing period.

Paddock size depends on three things: the AU of the herd, the amount of available pasture, and your grazing period, in number of days. Available pasture is the amount of pasture present in a paddock at the start of grazing, minus the amount remaining when the animals are removed from the paddock. We measure it in pounds of dry matter per acre. Depending on plant density, typical temperate climate pastures seen from roughly DC to Maine have about 300 pounds of forage dry matter per acre for each inch of height.11 There’s a bunch of factors that will impact that, but for the sake of simplicity, we’ll use this. Consult your university extension service or the USDA-NRCS for appropriate figures. The basic formula with this number is Available Pasture = inches before grazing - inches after grazing x 300 (your average pounds per acre per inch). If you turn a herd into a paddock when the pasture is 7 inches tall, and plan to take them off when the pasture is 4 inches tall, they consume 3 inches. We multiply that 3 inches by 300 lbs of forage dry matter per inch (for MA) and we have approximately 900 lbs of dry matter available per acre.

Now I want to circle back to what an AU is per day, because it’s important to understand paddock sizes, since you’ll want your animals to forage based on a number of days. One AU is 25 pounds per day, so you need a paddock with 25 pounds per day of edible forage per Au. Again, with my small chicken and goat livestock, it’s roughly half an AU per day, or about 13 pounds, to be on the safe side (and of course, chickens don’t actually live on forage, but let’s ignore that for now). There’s a ton of charts about pasture rates and days per paddock, but that’s super complicated and something you can Google, but I’m going to say I want to graze them for 2 days at a time per paddock. What you’ll find online is generally they’ll tell you how big of a paddock per acre based on an AU when your land produces 1000 pounds per acre, so you’ll have to adjust it to that dry matter figure we calculated for the northeast which was 900 pounds per acre. So, for half an AU moved every 2 days, I would need about 1000 square feet to feed my animals, or a 10x100 foot space. To go back to what I said earlier, I have almost double the land I need with 1 acre for my grazers, and that math checks out here— 1000 square feet times 26 rotations in the year is 26,000 square feet. Again, that doesn’t include the seasonality of species, but just to get a general idea, if you’re looking to get livestock, how big of a space you might need for, like me, a couple goats and some chickens. What you’ll generally find is the more often you move your animals, the more efficient they are at foraging and the less space you need, but the more time you need to devote to moving them. Of course, this is a bell curve, and eventually there won’t be any gain from rotation, while still increasing your work load, so finding that sweet spot is of particular value.

Protecting the Pasture

While we now understand the math behind the rotation for grazing to meet the animal’s demands, now we have to flip that around and see the demands of the pasture to stay healthy. The number of paddocks you'll need for a rotational grazing system will depend on: the number of days your animals graze in a paddock & the maximum summer rest period needed

To calculate the minimum number of paddocks, you'll divide the maximum number of rest days by the number of days grazing and add 1. Number of Paddocks = Max rest period ÷ number of days grazing + 1

Rest periods should be based on the growth rate of the pasture, which will vary with the season and weather conditions. Since growth rate is affected by soil productivity and fertility levels, even within a pasture system, rest periods will vary. The best way to manage this situation is to have a flexible rotational scheme, moving animals to those paddocks that have reached their optimum forage availability. Keep animals off a paddock until it reaches its desired optimum forage availability. What this means is you can’t just move your animals around a pasture like the handles on a clock unless you’ve got significantly more paddocks than your minimum rate, which also means you’re probably not actually getting the most out of your pasture. You’ll be, in part at least, following the seasonal growth of species as well as the various other pressures that increase or decrease growth in various parts of your pasture.

In the last piece, we had talked a bit about a sacrifice lots, and how they were useful in being a catch-all for a lot of different things that didn’t need 1 dedicated zone. One thing we had talked about was that these can be great locations for hay, and this is something to start thinking about in the spring. We also discussed that the spring rush of growth usually means you can’t get to all of the paddocks fast enough before the grass gets too long, so that it makes sense to consider cutting hay. Spring management usually involves diverting some of the paddocks out of the rotation scheme and using the forage for hay or silage. This effectively shortens the rest period between grazings and improves utilization of rapid spring growth.

But, how quick of growth are we talking? Obviously, every region is different, but in cool, moist areas springs, your rest only needs to be 10-14 days, but if your springs are dry, you’re looking at 14-20 days. Hot, moist summers are generally closer to 30 days of rest per paddock and dry hot summers are over 40 days of rest.12 So for me, to have my animals move across 1000 square feet for 2 days and move, and have up to 30 days of rest for some of the fields, I would need to have at least 15 fields, or 15,000 square feet, to accommodate those rest periods during the summer, although we can have some dry weather, so closer to 20,000 square feet in the form of 19 paddocks and a sacrifice lot that could occasionally be grazed would be ideal. Again, this doesn’t incorporate other factors like optimizing paddocks with certain species to maximize yield. This is really a starting point to fine tune an optimal system.

As you know, most forages grown for pasture in the northeastern part of the U.S. are cool-season plants. The majority of their growth occurs in spring and early summer, followed by a ‘summer slump’, when the growth slows, then by another small surge of growth in early fall.

So, I know that was a lot of information, and we’re not done yet on this subject matter. The reason I waited to drop the heavy information until the end is that I felt having framed up all of the other information, this would start to tie the different pieces together instead of feeling like a brain dump on you the first time you decided you wanted to learn a bit about grazing animals. So now we can look at those different pasture tools, and the complex knowledge of soil and pasture management, and now understand, once we build up a healthy pasture, not to break it into permanent paddocks, and we can, with some very wide accuracy, estimate how many animals we can have sustainably on our property. If you wanted a herd of sheep, you can do the quick math to see if you’ve got enough room, once the pasture is up and ready to go, for enough sheep that makes sense. By understanding the soil and grass function first, we can work into a sustainable animal load, instead of saying “I want 10 goats and 40 chickens” and trying to make it work, despite the fact it simply can’t.

And, of course, it’s not that simple anyway. The volume of forage required by grazing livestock isn’t a static figure. It can either: stays constant, or in brood herds, will increase as offspring graze larger amounts of forage as the season progresses.Therefore, the cool-season pasture growth curve creates a problem - too much forage in the spring and not enough in the summer. By harvesting hay and utilizing other resources, for example, tree hay, which we will be discussing at a later date, we will be able to help create balanced systems that reduce or eliminate feed inputs.

There are many good reasons to develop a rotational grazing system, including manure nutrient distribution. Having nutrients in the pasture, where we need them, is more economical than having nutrients building up in excess under trees, in shaded areas, or around mineral feeders.

One of the goals of your pasture management program should be to deposit as much manure and urine as possible directly back onto the pasture, as evenly as possible. A good pasture management program requires little to no additional fertilizer application beyond what is contained in the livestock’s manure and urine. The goal is that animals deposit as much manure and urine as possible directly back onto the pasture, as evenly as possible.

How do we manage pasture to effectively distribute manure? Basically, manure distribution becomes more even as grazing pressure becomes heavier. The University of Missouri Forage Systems Research Center has done research on manure pile distribution on 3-, 12-, and 24-paddock grazing systems. In the 3-paddock system, manure piles were concentrated within 150 feet of water and shade. Soil analysis showed that soil phosphorus levels were also significantly increased in the water and shade areas of the 3-paddock system.13

In comparison, the 24-paddock system had two to four times the density of manure piles in the main grazing area – and much less manure deposited close to water and shade. Furthermore, soil analysis showed that phosphorus levels stayed constant or decreased in the main grazing area. Manure distribution becomes more even as grazing pressure becomes heavier.

The researchers estimated that in a continuous grazing system it would take 27 years before every square yard of pasture received a manure pile. In the meantime, the livestock continue grazing and removing nutrients and depositing them in areas close to water and shade sources.

These figures clearly show that manure is more effectively distributed around the farm in a more intensive rotational grazing system. This has dual benefits through more consistent forage performance and significantly less nutrient inputs. Now, there are some things to consider for animal welfare when planning your species for grazing. To prevent problems with bloat, maintain alfalfa and clover concentrations in a pasture at 30 percent or less, as high concentrations of legumes cause bloat most commonly because of the high amounts of soluble proteins found within the plant.14

Prevention is the key to managing parasites and begins with proper pasture management. Because larva are found mostly in the bottom two inches of a plant, animals should be moved to a new paddock by the time the forage has been grazed down to three inches in height, which, coincidentally, aligns with our interests in keeping the grass healthy.

Typically, larva will go from the egg stage to the third larval stage in about six days, so moving animals every four to five days or less will also help to prevent internal parasite infections on pastures. Another aspect of parasite prevention hinges on the rest phase for the paddock. Experts are somewhat divided on exactly how long is long enough, but it is generally agreed that a long rest phase will help to break parasite cycles. Another prevention option is to graze other species of livestock to break the parasite life cycle. For example, sheep and goats share many of the same parasites but do not share parasites with cattle or horses.

It’s no surprise, then, when we hear about all of these different challenges on pastures, the requirements for soil rest, parasites, grass regrowth, and so on, that having dynamic multi-species systems that move quickly across pasture are the best for the long-term health of both the animals and the pasture itself. In doing this, we’re mimicking the natural cycles of both animals and pasture prairies in the wild. At this point, we’ve only scratched the absolute surface of pasture systems, but hopefully, if this is new to you, it wasn’t too intimidating, and maybe even something that sounded exciting. If this isn’t new to you, hopefully I didn’t confuse anything or deliver wrong information. I’m pretty sure I didn't because a lot of this content framework came from people a lot smarter than myself, but if I did, please let me know so I can fix it. In my experience, this works. And like I said in the second episode, if you’re curious but not ready to make such a plunge, consider chicken tractors as a stepping stone.

With that, we’re ready to wrap up this 3-part series on grazing. Hopefully you enjoyed it, and you felt like there was a lot more to the process than you thought. At the very least, hopefully you have a better appreciation of where your meat comes from, and if you don’t eat meat, hopefully you understand the complex web in which animals occupy as a part of building the health of planet.

If you’ve enjoyed this piece, which is equal to a 29 page chapter, of (so far) a 262 page book with 105 sources, you can support our work a number of ways. The first is by sharing this article with folks you think would find it interesting. The second is by listening and sharing the audio version of this content (Episode 15), the Poor Proles Almanac podcast, available wherever you get your podcasts. If you’d like to financially support the project, and get exclusive access to our limited paywalled content, you can subscribe on Substack or Patreon, which will both give you access to the paywalled content, and in the case of Patreon, early access to the audio episodes as well.

https://www.uvm.edu/sites/default/files/Agriculture/grazing/PDFs/Grazing%20Technical%20Assistance%20Resources/Infrastructure/Watering%20Systems/watering_systems_for_grazing_livestock.pdf

https://extension.missouri.edu/publications/eq380

Here’s an interesting dive into gleying ponds. http://simplingforall.blogspot.com/2015/10/gleying-pond.html

https://acsess.onlinelibrary.wiley.com/doi/abs/10.2134/agronj1965.00021962005700030016x

https://extadmin.ifas.ufl.edu/media/extadminifasufledu/cflag/image/docs/pdfs/spring-ranchers-forum/2015/Adesogan.pdf

https://www.mdpi.com/2076-2615/11/9/2623

https://www.sciencedirect.com/science/article/abs/pii/S0304401797001003

https://cals.arizona.edu/classes/ram456a/passmass.pdf

https://onlinelibrary.wiley.com/doi/abs/10.1111/j.1365-2494.1988.tb02137.x

http://extension.msstate.edu/sites/default/files/newsletter/forage-news/2011/7.pdf

https://extension.wvu.edu/files/d/bf695354-c317-4583-9352-b1a3e0d3cb54/forage-quality-of-rotationally-grazed-pastures-in-the-ne-1988-1990-seneca-trails-rc-d.pdf

Strickler, D. (2019). Managing pasture: A complete guide to building healthy pasture for grass-based meat & Dairy Animals. Storey Publishing.

https://uknowledge.uky.edu/igc/19/8/10/

https://grazer.ca.uky.edu/content/managing-legumes-spring-pasture-bloat